For this 7th loop of selection, powered by Innosuisse, we have again 10 ideas that have been submitted on our platform.

Discover here all the ideas and which partners they are looking for to win this selection and then make the feasibility study. Deadline: 21.05.2024 to put pledges.

Optimizing Coating Performances by Pulsed Laser-Assisted Magnetron Sputtering

by Sylvain Lecoultre, Haute école spécialisée bernoise (BFH)

Goal

“Diamond Like Carbon” or DLC are used as scratch-resistant coatings on watch glasses or as wear protection on razor blades, for example. The first objective is to explore the combination of Magnetron Sputtering with a high-power pulsed laser ablation of the target in order to produce nanocomposite films containing structures like nanoparticles or allotropic forms of carbon. The second objective is to make use of the flexibility of our SC1 reactor in order to combine Pulsed Laser Deposition, Magnetron Sputtering and ALD without breaking vacuum.

Partners wanted

We are primarily looking for industries active in the field of coatings for cutting tools, but also watchmaking or medtech industries interested in integrating nanoparticles into thin films by vacuum laser ablation for tribological, optical or decorative applications…

Environmental Framework Harmonization in Watchmaking Industries

by Sandra von Kaenel, GoCircular and Nicolas Roth, NRS PERFORMANCE Sàrl

Goal

Revolutionize sustainability practices within the watchmaking and microtechnical industries. By addressing fragmentation and lack of standardization in sustainability reporting, the project seeks to enhance efficiency, transparency, and collaboration across the sector. It aims to simplify, standardize, and harmonize sustainability questionnaires in watchmaking and microtechnical industries. This involves developing a unified calculation method and measurement framework to ensure comparability and consistency in results, ultimately saving time and money for stakeholders.

Partners wanted

Watchmaking brands, micromechanical industries developing these questionnaires, high schools to develop tools, sustainability specialists, producers, and subcontractors.

Sputtered Thermoelectric Thin Films For Self-Powered Wearable Devices

by Sylvain Lecoultre, Haute école spécialisée bernoise (BFH)

Goal

Our idea aims at addressing the evolving power supply needs of miniaturized, flexible, and wearable electronic products. The project focuses on harnessing the potential of thin film thermoelectric generators, which utilize the body’s heat as a free and renewable energy source. This idea focuses on testing different relatively cheap and non critical raw materials as potential candidate for Thermoelectric Generators TEG.

Partners wanted

The collaborating industries can provide valuable contributions to the project in several ways, including technical expertise especially for the scalability of the technology, process, and production. But overall, we would need your guidance within this project towards practical applications by sharing insights into market demands, regulatory requirements, and user expectations for thermoelectric materials in wearable electronics and commercialization pathway of this technology.

Al-Cu assembly by Transient Liquide Phase process (TLP)

by Randoald Müller, HEIG-VD

Goal

Connect copper with aluminium. If this difficult process is mastered, this assembly ensures both excellent electrical and thermal conductivity, while guaranteeing the lightness of the assembled system. The “Transient Liquid Phase” (TLP) method we propose here enables high-precision parts to be assembled without filler metal or melting. What’s more, the quality of the interface is close to perfection.

Partners wanted in

Electronics, aerospace, automotive, rail, etc. Many applications possible.

Galvanic deposition of metallic coatings onto titanium

by Oksana Banakh, Haute Ecole Arc Ingénierie

Goal

We propose a radically new electrochemical coating method of the titanium parts. The procedure combines a surface pretreatment step in non-aqueous media followed by an electrochemical coating. This method allows to significantly reduce production costs and time as the treatment can be done at the same production line by adding a short pretreatment step.

Partners wanted

We are looking for industrial partners interested to implement this new coating process and further develop it on an industrial scale. Also, end users coming from watch-making industry, jewelry and mechanical industry are welcome. The role of the industrial partners is to provide the parts to be coated and to evaluate the coating adhesion to the titanium substrate.

Automated Surface Inspection for Watches

by Huseyn Gasimov, Intelec Artificial Intelligence GmbH

Goal

The primary objective of this proof of concept project is to develop a prototype system for inspecting the glass covering of watches for scratches and imperfections. Key goals include:

- Designing a prototype platform capable of tilting in two directions to enable capturing images of watch surfaces at various angles.

- Integrating a high-resolution camera and light source onto the platform

- Developing defect detection algorithms to identify scratches and digs on watch surfaces

- Conducting tests to assess the accuracy and reliability of the system

Partners wanted

We’re looking for an advisor from academia who can advise the project team. We are also looking for watch manufacturers, who would like to give advice from the industry perspective and test our results in their production.

Angle-Independent Coloring by Laser-induced Plasmonic Effects on Metals

by Rainer Kling, Haute école spécialisée bernoise (BFH)

Goal

To develop and exploit a new way of color decoration of noble metals which has a much wider range of applications than conventional techniques due to the long-lasting topography effects without any chemical modification of the surface. The latest laser technology allows an angle-independent color effect to be achieved on noble metals, which is based on plasmonic effects. Here, blue and yellow colors are created using laser direct structuring without inducing any chemical changes (no oxide layer). It generates and embeds nanoparticles on the surface which show material specific plasmonic resonances. The colors of these resonances only depend on the particle size and are therefore angle-independent (in contrast to oxide layers).

Partners wanted

This technique is intended to be transferred to applications like security marks on luxury products and individualization of consumer products (watches, smartphones, wearables, etc.).

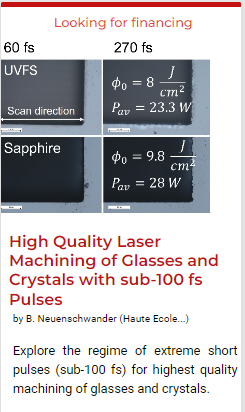

High Quality Laser Machining of Glasses and Crystals with sub-100 fs Pulses

by Beat Neuenschwander, Haute école spécialisée bernoise (BFH)

Goal

Preliminary experiments with an industry grade sub-100 fs system revealed a great potential for machining glasses and crystals with this technology. The high removal rate, compared to standard fs systems, was kept but the machining quality was strongly improved e.g. no chipping was observed at the edges. The goal is to exploit the sub-100 fs regime and its limits for machining of glasses and crystals concerning machining quality and efficiency also by going to shorter wavelengths (green and UV).

Partners wanted

We are looking for machine builders and companies machining glasses and crystals helping us to further explore this promising technology and estimate its limits. A combination of partners from both fields would be very beneficial as a laser machining compagnie cannot work without a machine and a machine builder will not offer this technology without possible applications. The partners will gain a clear picture with advantages and disadvantages of this new technology for their designated application and material.

Multifunctional PVD coating for watch items and cutting tools

by Oksana Banakh, Haute Ecole Arc Ingénierie

Goal

We propose a new black wear-resistant PVD coating with two more functionalities, lubricating properties at higher temperatures (for cutting tools) and an antimicrobial effect (watchmaking and jewelry). These functionalities would be achieved by the incorporating of a small amount of silver into a CrAlN coating, known for its black color and wear resistance. Our project aimed at the development of new multifunctional coating, a Ag-doped CrAlN thin film deposited by reactive magnetron sputtering (PVD). This is extremely important for applications in cutting tools working at high temperatures. Secondly, silver doping usually results in the antimicrobial properties. This functionality is desirable in decorative applications (watch cases, jewelry)

Partners wanted

Manufacturers of cutting tools, watch components or watch subcontractors. The industrial partners who join the project will be responsible for a proving of the industrial parts and for an evaluation of the performance of the coated items.

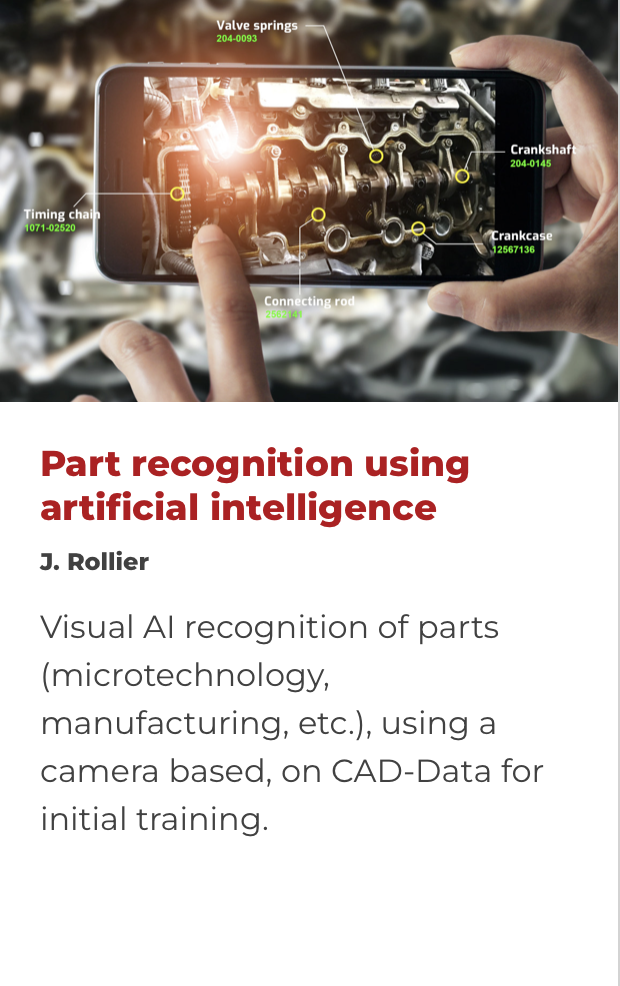

Part recognition using artificial intelligence

by Joël Rollier, KAÏNOO Sàrl

Goal

Create a system that, given a part, assembly or machine, can correctly identify it from a pre-trained database, using a smartphone or tablet. The innovation lies in the way we handle the training step for the parts: the augmented reality system will be trained by feeding in 3D CAD data, instead of images/photos. This will allow to simply integrate the system into your workflows without needing a manual labor.

Partners wanted

Academic partners, people that work with or manufacture parts: we want to test the system using actual 3D model CAD data and validate its precision against real parts input from people in the field to analyse their needs and also estimate the improvement that such a system could provide.