For this 6th loop of selection, powered by Innosuisse, we have again 14 ideas that have been submitted on our platform.

Discover here all the ideas and which partners they are looking for to win this selection and then make the feasibility study.

Metallic glass 3D sintering to complex shapes

by Konrad Papis, inspire AG

Goal

Shaping the unshapable. Produce parts with unprecedented material properties, freeform and hollow shapes, and scalable in size. Combine an ultra-fast Spark Plasma Sintering (SPS) process, with additively manufactured water-soluble lost molds, to produce 3D parts from Bulk Metallic Glasses (BMG).

Partners wanted

From jewellery to microtechnology, and from electric to mechanical and fluidic components; furthermore, watch components such as housings, gear wheels, screws, and springs, components for electric motors, bearings, and hubs – the list of potential applications is long.

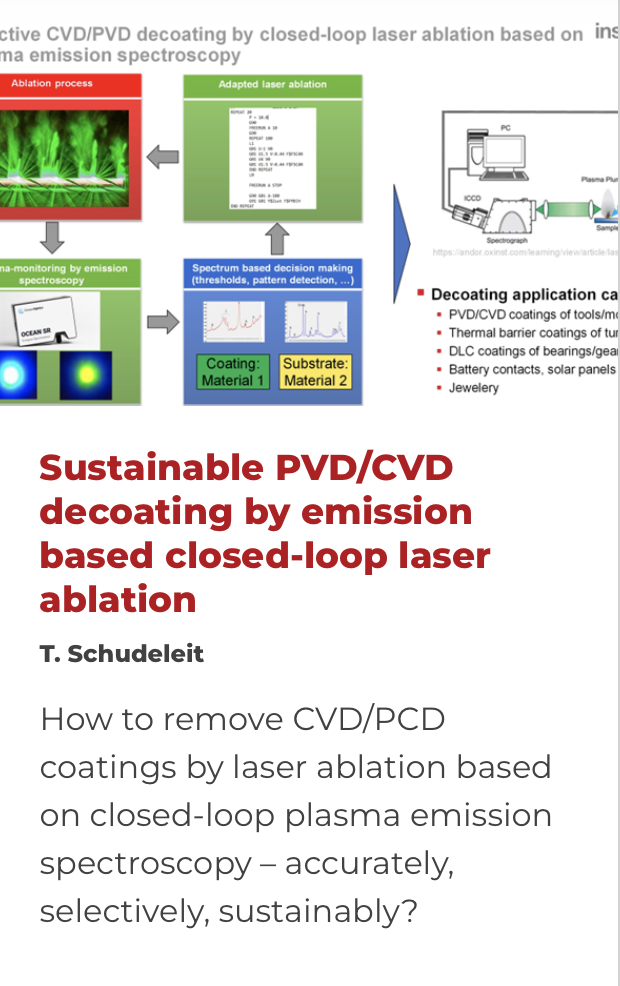

Sustainable PVD/CVD decoating by emission based closed-loop laser ablation

by Dr. Timo Schudeleit, inspire AG

Goal

Develop a closed-loop laser ablation process that allows selective removal of hard coatings. Detect when the coating material has been fully removed: the plasma emission curve changes during laser processing with the ablated material composition. Based on this information, the laser process will automatically be adjusted to avoid damaging the substrate.

Partners wanted

Applications can be cutting tools, gears, bearings, turbine blades or watches.

Sputtered Thermoelectric Thin Films For Self-Powered Wearable Devices

by Sylvain Lecoultre, BFH

Goal

Our idea aims at addressing the evolving power supply needs of miniaturized, flexible, and wearable electronic products. The project focuses on harnessing the potential of thin film thermoelectric generators, which utilize the body’s heat as a free and renewable energy source.

Partners wanted

The collaborating industries can provide valuable contributions to the project in several ways, including technical expertise especially for the scalability of the technology, process, and production. But overall, we would need your guidance within this project towards practical applications by sharing insights into market demands, regulatory requirements, and user expectations for thermoelectric materials in wearable electronics and commercialization pathway of this technology.

Al-Cu assembly by Transient Liquide Phase process (TLP)

by Randoald Müller, HEIG-VD

Goal

Connect copper with aluminium. If this difficult process is mastered, this assembly ensures both excellent electrical and thermal conductivity, while guaranteeing the lightness of the assembled system. The « Transient Liquid Phase » (TLP) method we propose here enables high-precision parts to be assembled without filler metal or melting. What’s more, the quality of the interface is close to perfection.

Partners wanted in

Electronics, aerospace, automotive, rail, etc. Many applications possible.

AI-based Quality Assessment of High Quality Surfaces

by Roger Herger, maXerial AG

Goal

Develop an AI-based quality assessment of high quality surfaces. This can form an excellent basis for further experimental work, e.g. in the field of industrial process control using X-ray technology through 2D or 3D imaging techniques such as industrial computed tomography (CT).

Partners wanted

Academic partners, watchmakers, med tech companies (implants,..)

Automated Optical Inspection of Printed Circuit Boards

by Husein Gasimov, Intelec Artificial Intelligence GmbH

Goal

Detect tiny dust particles and excess flux on a PCB board. This inspection can’t be performed using most of the traditional AOI instruments, which are on the market today.

Partners wanted

Academic partners, who already have some experience in PCB inspection, and PCB manufacturers, who would like to test our results in their production.

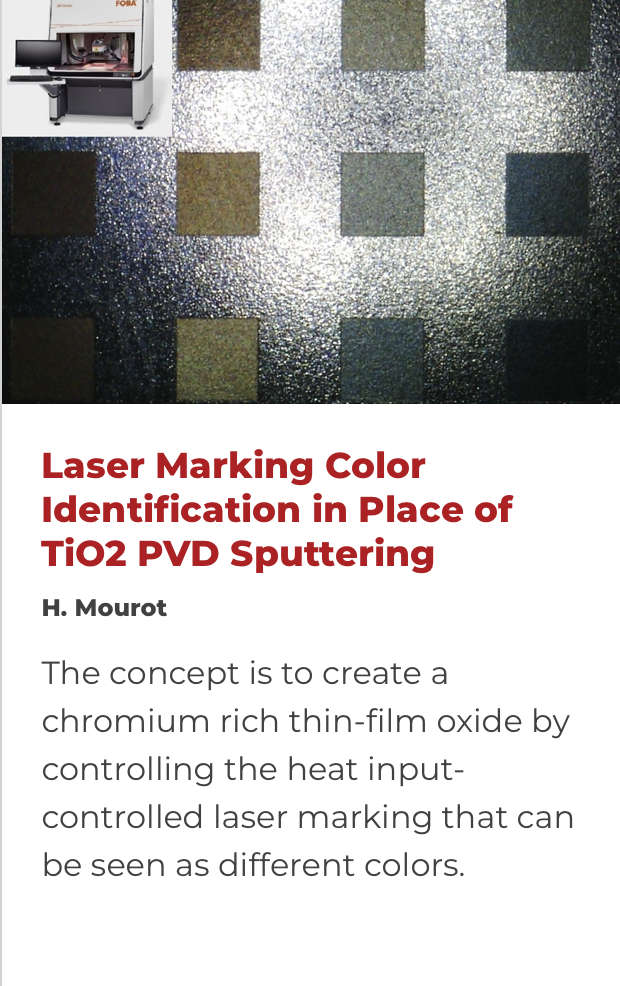

Laser Marking Color Identification in Place of TiO2 PVD Sputtering

by Hélène Mourot, Jabil Healthcare

Goal

Create a chromium rich thin-film oxide by controlling the heat input-controlled laser marking on the surface that can be seen as different colors by the viewer and determine the feasibility of implementing the substitution of sputter coating to laser marking stainless steel screws.

Partners wanted

Academic partners, industrial partners who have the same problematic or ideas on how to work on this topic.

Enhanced scratch resistance of anodized TiO2 by invisible pulsed laser treatment

by Sylvain LeCoultre, BFH

Goal

Enhance the scratch and abrasion resistance of coloured surfaces produced by anodized TiO2.

Partners wanted

We are looking for companies active in the medtech, aeronautics, watchmaking and jewellery or other sectors to test our tribological solution on surfaces measuring less than 5x5cm2.

Record machine maintenance operations in VR autonomously on a digital twin

by Joël Rollier, KAÏNOO Sàrl

Goal

Extend the digitization of the technical documentation for maintenance operations and repair processes on manufacturing machines (CNC, turning, etc.). The aim of the project is to build a system that allows experts to record these processes directly on a complete digital twin of the machine, allowing them to operate independently.

Partners wanted

Manufacturing industry (medical, machinery, parts) that wants to digitize its technical documentation for maintenance operation and/or repair processes. We will need a full CAD model of the machine to be reproduced (you will be able to omit parts with industry secrets, those will not appear in the application or will be represented in a simplified way). You may be a machine manufacturer or the owner of a manufacturing facility.

Micro Machining polishing to replace Vib. Grinding + EP on titanium implant

by Hélène Mourot, Jabil Healthcare

Goal

Work on all parameters of machining (programming, tool, lubricant) to achieve the same surface quality directly after mechanical machining and so simplifying the process by removing 2 finishing steps vibratory grinding and electropolishing, and to determine in which extend the surface can be achieved.

Partners wanted

Skills required are expertise in machining, tools, lubricants. Ultrasonic assistance could be a way to explore as well.

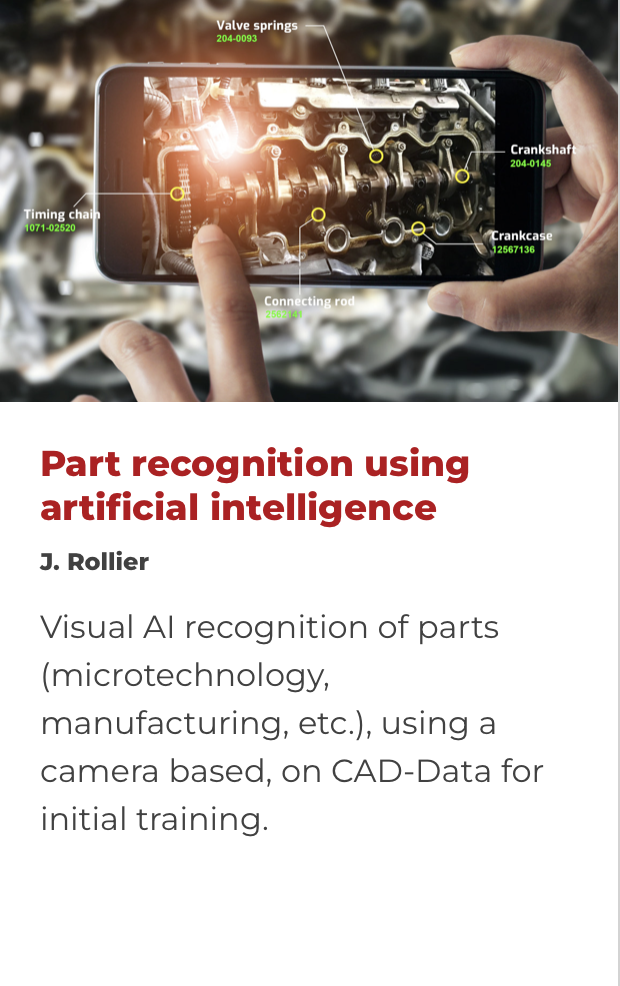

Part recognition using artificial intelligence

by Joël Rollier, KAÏNOO Sàrl

Goal

Create a system that, given a part, assembly or machine, can correctly identify it from a pre-trained database, using a smartphone or tablet. The innovation lies in the way we handle the training step for the parts: the augmented reality system will be trained by feeding in 3D CAD data, instead of images/photos. This will allow to simply integrate the system into your workflows without needing a manual labor.

Partners wanted

Academic partners, people that work with or manufacture parts: we want to test the system using actual 3D model CAD data and validate its precision against real parts input from people in the field to analyse their needs and also estimate the improvement that such a system could provide.

Syringes inspection demonstrator based on machine learning

by Tristan Salomon, Axom Solution SA

Goal

Build a demonstrator that can be used to test the performance of the inspection of 1 unit per second. The fact that we use deep learning enables us to have a more compact and faster to deliver solution.

Partners wanted

Special machine building (simple rotating plate),

Vision systems definition (light, camera, lense),

Defect definition (phamaceutical manufacturer).

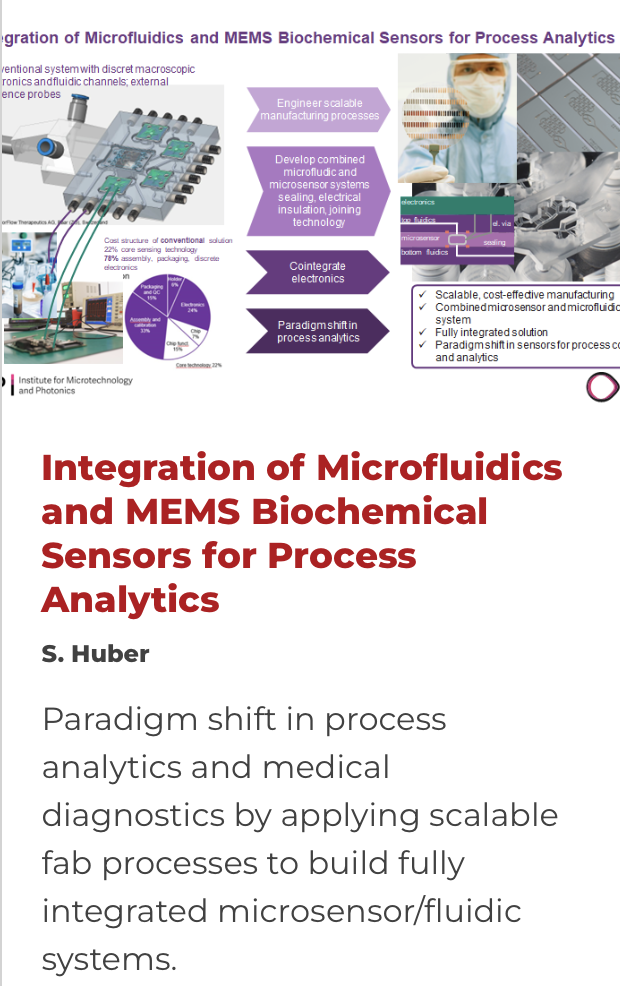

Integration of Microfluidics and MEMS Biochemical Sensors for Process Analytics

by Samuel Huber, Uni OST

Goal

We aim for a paradigm shift in microsensors and fluidics for process analytics by targeting a fully integrated and cost-effective system. Our objectives are threefold: (i) developing a technical solution for biochemical sensor assembly and packaging, (ii) building an ecosystem of market know-how and technologies by bringing together key customers and suppliers, and (iii) joint development of a biochemical sensor roadmap for addressing current and future market needs and developing the required technologies.

Partners wanted

Biochemical sensing, precision liquid dispensing for sensor functionalization, microfluidics fabrication and packaging, manufacturers of bioreactors, integration of electronics in biochemical sensing.

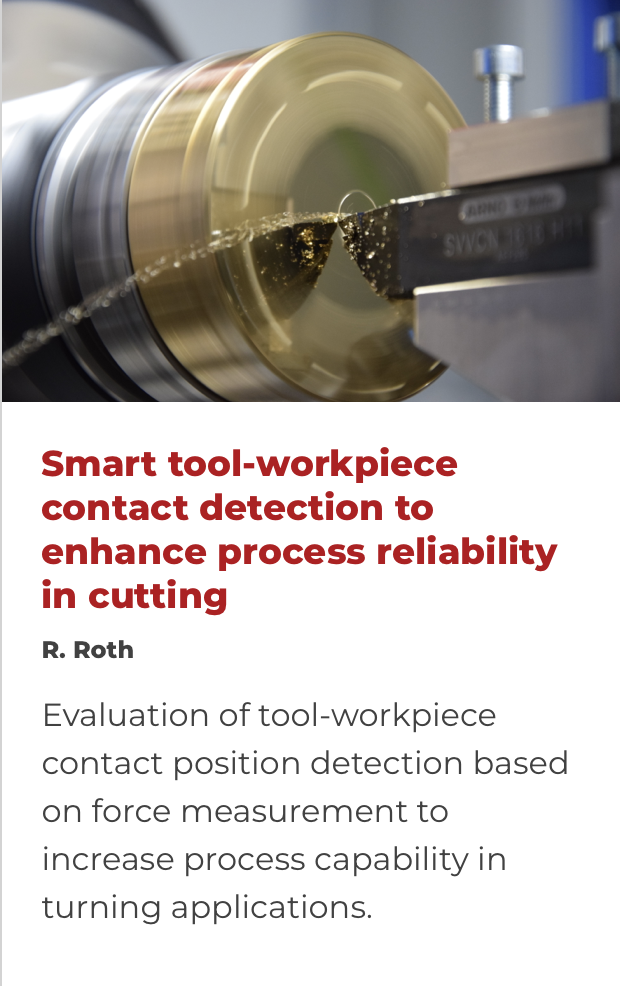

Smart tool-workpiece contact detection to enhance process reliability in cutting

by Raoul Roth, Rhysearch

Goal

Determine the potential for increasing the process capability of turning applications by tool-workpiece position detection based on force measurements. The focus is on turning operations and the determination of the Z-position of the tool relative to a given workpiece surface.

Partners wanted

Companies that struggle with the precision and process capability of turning processes (due to wear, drift, etc.) and can benefit from implementing the idea, or companies that are interested in contributing their own hardware or software (machine, sensorics, …), which in turn can be used for future services based on the idea.